Flexible Intermediate Bulk Containers (FIBCs)—also known as bulk bags, jumbo bags, or super sacks—are large industrial packaging solutions made from woven polypropylene. Designed to store and transport dry, flowable materials such as grains, fertilizer, chemicals, plastic granules, and construction aggregates, FIBC bags offer an efficient, safe, and cost-effective bulk packaging option used across multiple industries.

FIBC Manufacturing Process

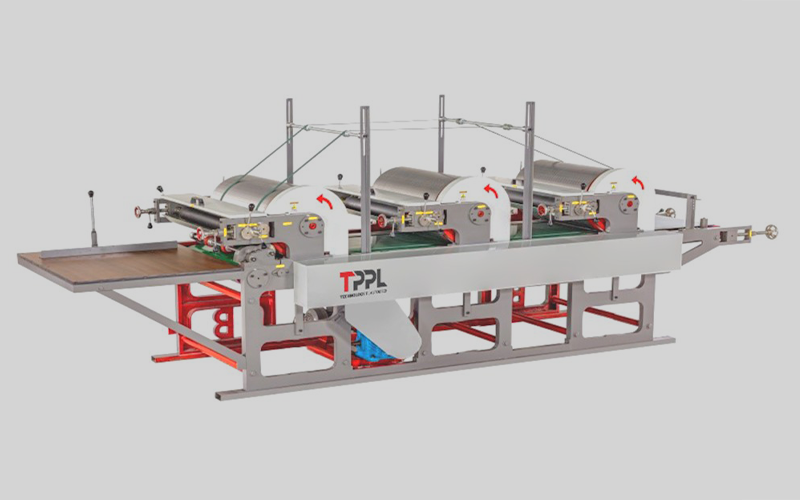

At TPPL, we offer a complete solution for FIBC manufacturing with precision-engineered machinery:

1. Superior Load Capacity & Safety

• Designed to handle weights from 500 kg to 2000 kg

• Certified for UN-approved and food-grade applications

2. Versatility Across Industries

• Fertilizer bags, chemical bags, agriculture packaging, cement bags, and more

• Ideal for grains, seeds, powders, flakes, and granules

3. Cost-Effective Bulk Packaging

• Reusable, recyclable, and space-saving

• Reduces packaging costs by up to 30% compared to rigid containers

4. Customization & Safety Compliance

• Available in Type A, B, C, and D FIBCs to meet static control requirements

• Custom filling/discharge systems for dust-free operation

TPPL is a leading manufacturer of FIBC bag making machines, helping you build scalable, sustainable, and profitable bulk bag production lines. Whether you produce FIBC for chemicals, food, or construction, TPPL’s machinery ensures the best quality at optimal cost.